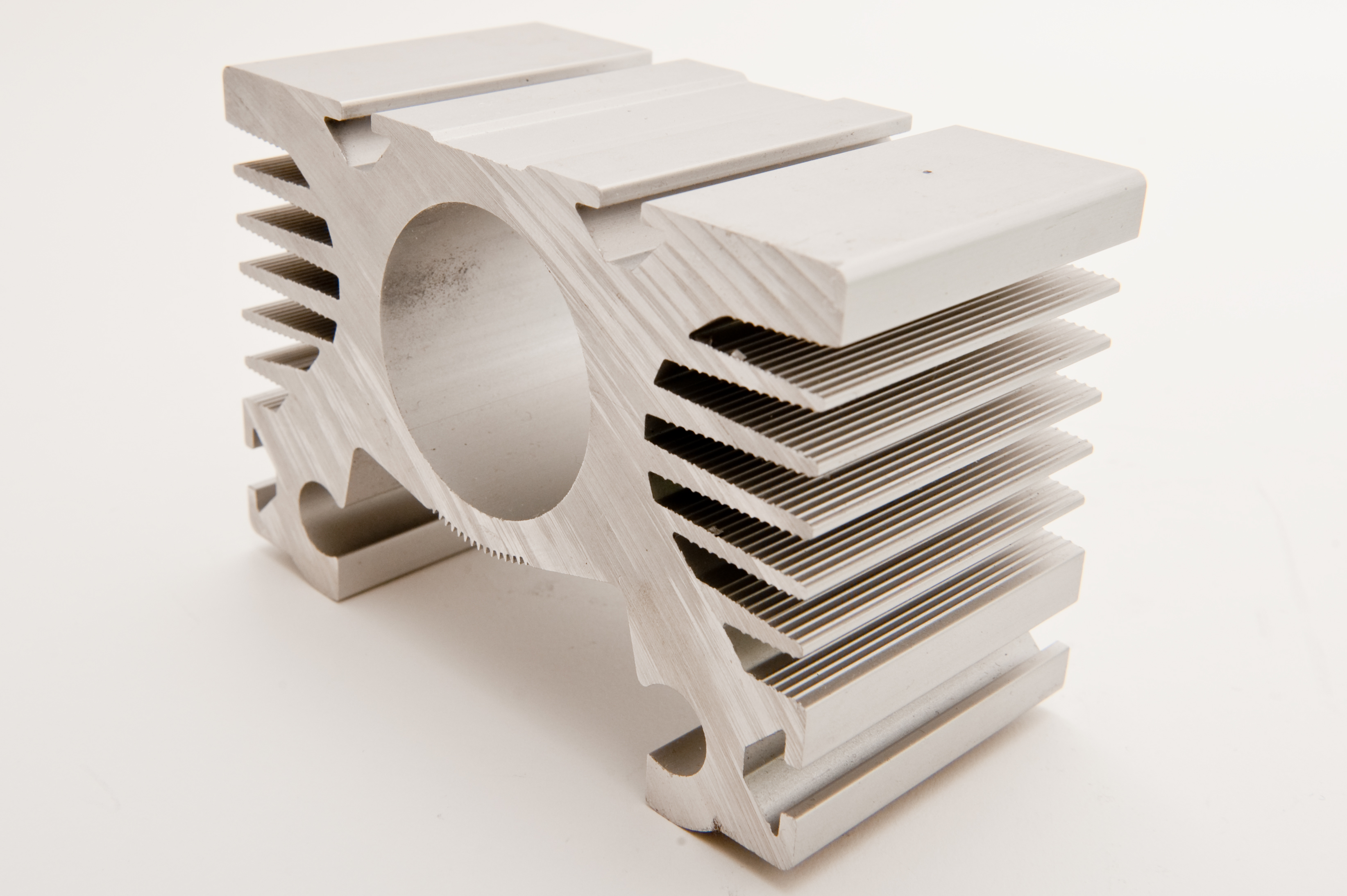

Aluminum Anodizing

Anodizing is an electrochemical process that creates an oxide layer far thicker and more durable than what nature would produce on its own. This surface can accept a variety of colours, most of which are translucent

Anodized finishes are:

Long-lasting

Scratch-resistant

Non-conductive

Weather-resistant

Easy to clean

Aesthetically pleasing

Acid Etching

An alternative to caustic etching, acid etching uses fluoride-based ions to modify the surface of aluminum. This method creates a finished product that has a more consistent matte finish and enhanced aesthetic appeal. Additionally, because this process produces less waste, it is the more environmentally friendly etching option

Electrolytic Colouring

Also called two step or two stage colouring, anodized aluminum parts are immersed in an electrolyte bath. This electrolyte bath contains metal salts which are deposited into the coating. An electrical current is then passed through the solution which causes the colour of the finish to change from champagne to standard bronze all the way to black.

The Resulting Oxide Layer

Following the electrolytic colouring process, the resulting oxide layer is corrosion resistant and is extremely hard; it will not chip, flake or peel, providing the utmost in durability. Due to these properties, anodizing continues to be a popular finishing choice for a range of applications including architectural, marine products, furniture, lighting, electronics and more.

Address

288 Don Park Road

Markham, ON L3R 1C3

Call Us

Tel: 905.475.1229

Fax: 905.475.8056